- Home

- Products

- Honing Machine

- Vertical Honing Machine (Vertical Machine for Single Pass Tool)

Vertical Honing Machine (Vertical Machine for Single Pass Tool)

From the beginning, Honing has been dedicated to the R&D and manufacturing of premium honing products and provided customers with excellent honing solutions. The LDH-86 vertical honing machine for precision hole honing is a great product that we have developed based on our years of experience.

Equipped with a Siemens PLC device, servo cam turntable, steel-structured lathe body, lifting system, cooling system and other advanced devices, this vertical standing honing machine is easy to operate. When matched with single stroke honing tools, it has a high honing precision, a high working efficiency, easy operation and requires very little maintenance, making it suitable for the batch production of parts with high precision holes, especially in gears and work pieces that have strict requirements for honing precision with only one honing operation.

Features

1. It requires very little maintenance for its stainless steel parts, as it is resistant to corrosion, colorfast, and it is safe to operate while keeping the workplace clean.

2. It is capable of storing several setup programs for multiple parts.

3. As it comes equipped with a lifting system that consists of ball screws and a linear guide, it is easy to set the vertical height.

4. The steel plate on the vertical honing machine ensures the work piece is firmly clamped.

| Bore Range | φ10 mm- φ50mm |

| Spindle Speed | 0-1500RMP(stepless adjustment) |

| Spindle Motor Power | 4kw/5.5kw |

| Quantity of Spindle | 4 /6 |

| Stroke Speed | 0-105mm/sec |

| Stroke of Spindle | 720mm |

| Stroke Motor Power | 2.5kW (Ac Servo Motor) |

| Turntable Rotary Speed | 0-3mm/min(Frequency Conversion Stepless Variable Speed) |

| Motor Indexing Mechanism | 0.75kW |

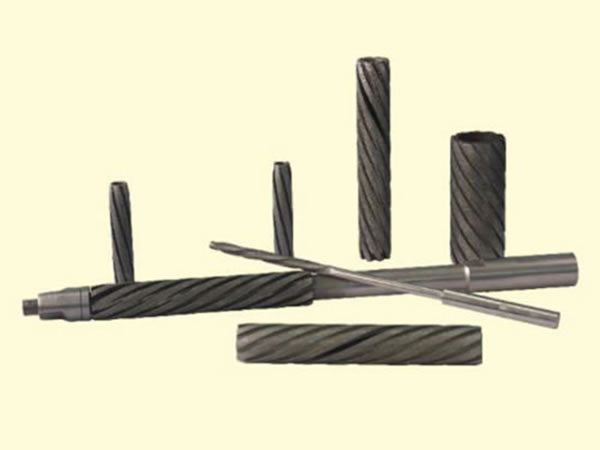

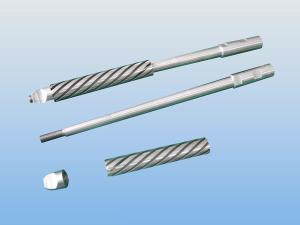

| Tools Code(Abrasives sleeve with diamond plated) | Grit size number |

| D1 | 60-70 |

| D3 | 100-120 |

| D5 | 200-230 |

| D7 | 240-300 |

| D8 | 325-400 |

| D0 | 600 |

| D00 | 1200 |