- Home

- Products

- Honing Machine

- Vertical Honing Machine (Machine with Vertical Honing Tools for Honing Cylinder Liner)

Vertical Honing Machine (Machine with Vertical Honing Tools for Honing Cylinder Liner)

Along with the horizontal honing machines, we also manufacture vertical honing machines. The LH-60 described here is among one of our first vertical honing machines for honing cylinder liners during which vertical needs are required. It can be paired with common vertical honing tools (such as the CK series) and single stroke honing tools.

We specialize in the R&D and manufacturing of honing equipment, honing tools, stones and other related products. We can provide both standard and customized products, and strive to provide our customers with the best honing solutions. For more information about honing solutions and services, please contact us.

Technical Data| Spindle motor power | 2.2kW |

| Speed adjustment range | 90-350RPM |

| Stroke motor power | 0.75kW |

| Speed adjustment range | 40-80RPM |

| Stroke length | 0-225mm |

| Range of hole diameters | 19-203mm |

| Maximum load for working table | 680kg |

| Maximum dimension for working table | (length)1168mm*(width)558mm*(height)673mm |

| Oil pump motor | 2.2kW |

| Honing oil volume | 206L |

| Power supply | 220V, 50Hz, 3Ph |

| Boundary dimension | (Width)2280mm*(length)1842mm*(height)2198mm |

| Net weight | 861 kg |

| Shipping weight | 1134kg |

| Color | Pearl |

Features

1. Intelligent Operation: As it is equipped with a PLC device and a touch screen monitor that displays real time data in regards to the working status, this vertical honing machine's honing parameters are easy to adjust.

2. Automatic Feeding: During the honing operation, the stone is automatically fed in order to ensure the highest honing efficiency.

3. Precise Control: The non-stop and time controlled operation mode features a precise control and as a result, makes the honing more accurate.

4. High Accuracy in Honing: The machine provides and automatic or manual high accuracy in three different positions: upper, lower and middle.

5. Wide-Range Speed Adjustment: The spindle and the stroke adopt an independent frequency converter and a variable frequency motor.

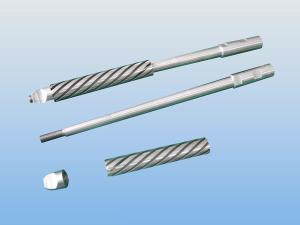

6. Advanced Honing Tools: As it is matched with different honing tools, this vertical honing equipment can handle workpieces with different specifications and are made from different materials.

Major Functions

1. As both the spindle motor and the stroke motor are variable frequency motors, the honing equipment has a stepless speed adjustment function. The stone feeding speed and the honing speed can be adjusted automatically depending on the stone properties.

2. The non-stop and time controlled operation modes and the short-pause at three different positions (Upper, middle, lower) ensures a highly accurate control over the honing precision.

3. A human to machine interface on this vertical honing equipment makes the operations and settings much easier. It can also display some data, such as hole shape and netted angles.

4. It comes equipped with multi-stones and diamond tools. This machine can meet high requirements for hole dimension, shape and finishing. That assists in making plateau honing cross hatches.