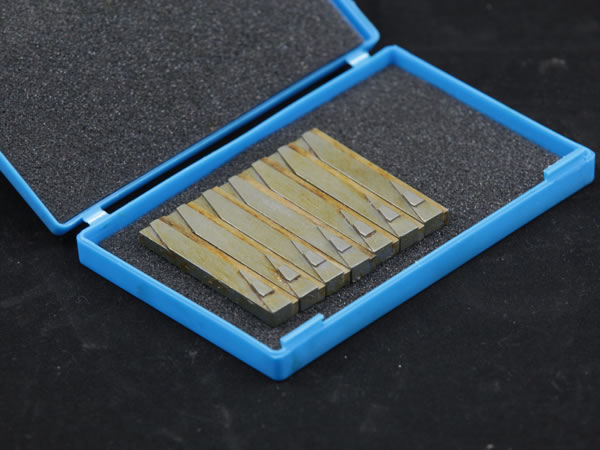

Honing Stone (Abrasive Stone)

A honing stone is an abrasive that is matched with other honing tools and then installed on honing machines to process parts with bores. They are highly efficient, have a high honing precision, a fine finishing, and a reliable repairing performance, making them suitable for honing applications in the machining industry. The most commonly used abrasive materials include diamond stones, cubic boron nitride stones, alumina stones and SiC stones.

As a professional manufacture of honing product, we provide high quality stones made from premium abrasive materials. Based on an advanced formula and processing technology, these abrasive stones have a longer lifespan and significantly improve the honing efficiency.

Application| Abrasive Materials | Code | Application | Notification |

| Cubic Boron Nitride | NM | Quenched steel and tempered Steel | |

| Diamond | DM | Cast iron, aluminum, copper, carbide, ceramics and other materials | |

| Alumina | A | Quenched and tempered steel | |

| SiC | J | Aluminum, copper alloy and cast iron |

The above stone can match both a single-stone holder and the multi-stone holders. For example, the No. P28 stone holder is suitable for stones and sandbars numbered P28NM, P28DM, P28A and P28J.

Grit Size Number| No.(set by HONGNING) | Grit size |

| 3 | 100 |

| 4 | 150 |

| 5 | 220 |

| 6 | 280 |

| 8 | 400 |

| 9 | 500 |

| 0 | 600 |

| 90 | 900 |

| 00 | 1200 |

| Hardness No. | |

| Soft↓Hard | 3 |

| 5 | |

| 7 | |

| 9 | |

| 11 | |

| 13 | |

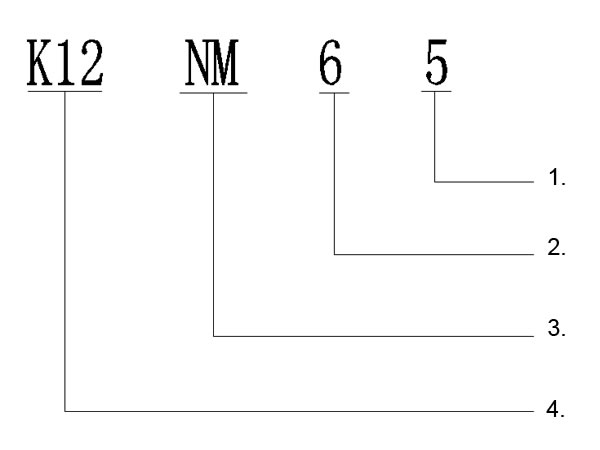

1. Hardness

2. Grit Size

3. Abrasive Materials

4. Series No.

Note: all stones are marked in the same way of the K12 stone.

Selection Reference Table| Grit Size | 3- (100#) |

4- (150#) |

5- (220#) |

6- (280#) |

8- (400#) |

9- (500#) |

0- (600#) |

90- (900) |

00- (1200) |

|

| Material | Abrasive type |

Roughness (μm) | ||||||||

| Hard Steel | Alumina/SiC | - | 0.50 | 0.45 | 0.30 | 0.12 | 0.08 | 0.03 | - | - |

| Cubic Boron Nitride | 1.40-2.00 | 1.15 | 1.00 | 0.70 | 0.50 | - | 0.18 | 0.10 | 0.05 | |

| Soft Steel | Alumina /Sic | - | 0.9-1.40 | 0.65 | 0.50-0.9 | 0.18-0.25 | 0.10-0.20 | 0.05 | - | - |

| Cubic Boron Nitride | 1.60-2.5 | - | 1.25-2.0 | - | 0.65 | - | 0.40 | 0.25 | 0.12 | |

| Cast Iron | SiC | - | 0.75-1.0 | 0.50 | 0.30 | 0.15 | 0.12 | 0.08 | - | - |

| Diamond | - | - | 2.00 | - | 1.27 | - | 0.50 | 0.40 | 0.30 | |

| Nonferrous Metal | SiC | 4.30 | 2.00 | 1.40 | 0.85 | 0.40 | 0.30 | 0.05 | - | - |

| Hard Alloy | Diamond | - | 0.75 | 0.50 | - | 0.18 | - | 0.08 | 0.05 | 0.03 |

| Ceramic | Diamond | - | 1.27 | 1.00 | - | 0.50 | - | 0.40 | - | 0.25 |

| Glass | Diamond | - | 2.40 | 1.80 | - | 0.75 | - | 0.40 | 0.30 | 0.20 |

| Honing allowance |

0.05-0.10mm | 0.02-0.05mm | 0.01-0.02 | <0.01 | ||||||